Polysense Expands iEdge4.0 powered SW-defined Sensors Portfolio with New Ultrasonic and mmWave Radar Ranging Products

Expanded portfolio bridges the gap between cost-efficiency and mission-critical reliability across smart infrastructure and industrial automation

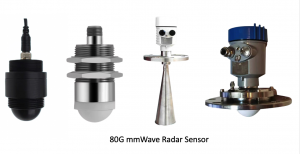

SANTA CLARA, CA, UNITED STATES, February 26, 2025 /EINPresswire.com/ -- Polysense Technologies Inc., a leading innovator in the field of software-defined sensors, is pleased to announce the latest addition to its iEdge4.0-enabled product lineup: a series of ranging products based on ultrasonic and 80G mmWave radar principles. This expansion further enriches Polysense's portfolio of SW-defined sensors, offering advanced solutions for a wide range of applications.

The new release addresses a critical industry challenge with the dual-technology synergy: balancing precision, environmental resilience, and total cost of ownership in level measurement. By offering complementary ultrasonic and radar technologies under a unified software platform, Polysense empowers users to deploy hybrid sensing architectures tailored to evolving operational needs.

Building on the success of its existing ultrasonic products, including the PSS-36301x to PSS-36306x series, Polysense has introduced the PSS-363071 to PSS-363076 series of ranging products. These new sensors are designed to monitor liquid levels from 1 meter to 20 meters, such as river levels, providing accurate and reliable data for various environmental monitoring scenarios.

In addition to the ultrasonic offerings, Polysense has also launched a series of mmWave radar-based products, the PSS-377191 to PSS-377199 radar level products. These radar solutions are specifically tailored for complex monitoring environments, such as industrial sites with high temperatures, humidity, and various interferences. The 80G radar technology complements the ultrasonic products by addressing their limitations in challenging conditions, ensuring robust and precise measurements.

With the advancement of technologies and the economies, the smart sensors demand is growing faster in various area, esp. demand for advanced liquid level monitoring, the solutions has been driven by the growing need for precise and reliable data in various industries, including agriculture, environmental monitoring, and industrial automation, the market has seen a rise in demand for sensors that can operate in harsh environments and provide high-precision measurements. The new ultrasonic and radar ranging products from Polysense are designed to meet these demands, offering versatile solutions for different applications. For instance, the ultrasonic products are ideal for monitoring liquid levels in rivers and small to medium-sized containers, while the radar products are suited for large storage tanks and complex industrial environments.

"The integration of advanced technologies like ultrasonic and radar sensing with SW-defined sensors technology in IoT devices is a significant step forward in the industry. Polysense's new products are well-positioned to address the growing demand for high-precision and reliable liquid level monitoring solutions." Said Alex Wu, the President and CEO of Polysense Technologies.

Key Distinctions Between Ultrasonic and mmWave Radar Level Meters

Measurement Principle:

o Ultrasonic Level Meters: Utilize the transmission and reception of ultrasonic pulses, calculating liquid levels based on the time-of-flight and reflected signals in the air.

o Radar Level Meters: Emit high-frequency electromagnetic waves (e.g., 80GHz) and determine liquid levels through the reflection and propagation time of these waves.

Measurement Accuracy:

o Ultrasonic Level Meters: Generally offer centimeter-level accuracy, significantly affected by medium properties (e.g., temperature, humidity, density) and environmental factors (e.g., dust, steam).

o Radar Level Meters: Achieve millimeter-level accuracy, with minimal environmental impact, making them suitable for high-precision measurements.

Environmental Adaptability:

o Ultrasonic Level Meters: Suitable for normal pressure and low-temperature environments (generally not exceeding 80℃), and are sensitive to foam, steam, and dust.

o Radar Level Meters: Highly adaptable, capable of operating in high-temperature(up to 200℃), high-pressure, dusty, or steamy environments, unaffected by medium temperature and pressure.

Interference Resistance:

o Ultrasonic Level Meters: Prone to electromagnetic interference, wind speed, and obstacles, resulting in less stable measurements.

o Radar Level Meters: Strong interference resistance, effectively suppressing interfering echoes for more stable measurements.

Installation and Maintenance:

o Ultrasonic Level Meters: Complex installation requiring consideration of blind zones and sound wave propagation paths, potentially needing additional brackets or piping.

o Radar Level Meters: Simple installation, directly mounted on the top or side of containers, with low requirements for installation position and angle.

Cost:

o Ultrasonic Level Meters: Lower cost, ideal for budget-constrained applications with less stringent accuracy requirements.

o Radar Level Meters: Higher cost, but superior performance, suitable for complex conditions demanding high measurement accuracy and stability.

Applicable Scenarios:

o Ultrasonic Level Meters: Suitable for small to medium-sized containers in simple environments, such as clear water pools and small storage tanks.

o Radar Level Meters: Ideal for large storage tanks and complex conditions (e.g., high-temperature, high-pressure, dusty, or steamy environments), such as oil storage tanks and chemical storage tanks.

In conclusion, the choice between ultrasonic and radar level meters depends on specific application requirements and environmental conditions. For high precision, strong interference resistance, and adaptation to complex environments, the mmWave radar level meters are the preferred choice. For budget-limited and simpler environments, ultrasonic level meters offer cost-effective solutions.

Polysense's new ultrasonic and radar ranging products, integrated with the iEdge4.0 OS, provide versatile and advanced options for liquid level monitoring, catering to diverse industry needs and further solidifying Polysense's position as a pioneer in the IoT sensor market.

About Polysense:

Established in Santa Clara, California, Polysense is dedicated to providing comprehensive, end-to-end solutions for the IoT market. Powered with its iEdge 4.0 OS and advanced configurable, modular open architecture, Polysense SW-defined sensors technology simplifies sensing complexity and reduces costs in real-world applications.

Press Contact:

Alina Wu at PR@polysense.net.

Product inquiry:

- https://www.polysense.net

- Email: sales@polysense.net

Polysense Sales

Polysense Technologies Inc

Sales@Polysense.net

Visit us on social media:

Facebook

X

LinkedIn

Distribution channels: Chemical Industry, Energy Industry, Environment, Food & Beverage Industry, Healthcare & Pharmaceuticals Industry

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release